- More mobility in the fields of trade, industry and service

- For removing rusted and stuck drive shafts directly on the vehicle

- Working time approx. 5 minutes only

- For all passenger cars with 4- and 5-hole wheel hubs due to countersunk slotted holes for wheel bolts

- Prevents heating of or damage to the drive shaft or damage to other parts

- Application: screwing the wheel hub on with the vehicle wheel nuts, removing the drive shaft with a 18 tonne or 22 tonne hydraulic cylinder (the installation of the impact body enables additional force by using a hammer), removal of the wheel hub with sliding hammer V2922 and adapter V2872

- Including multibox

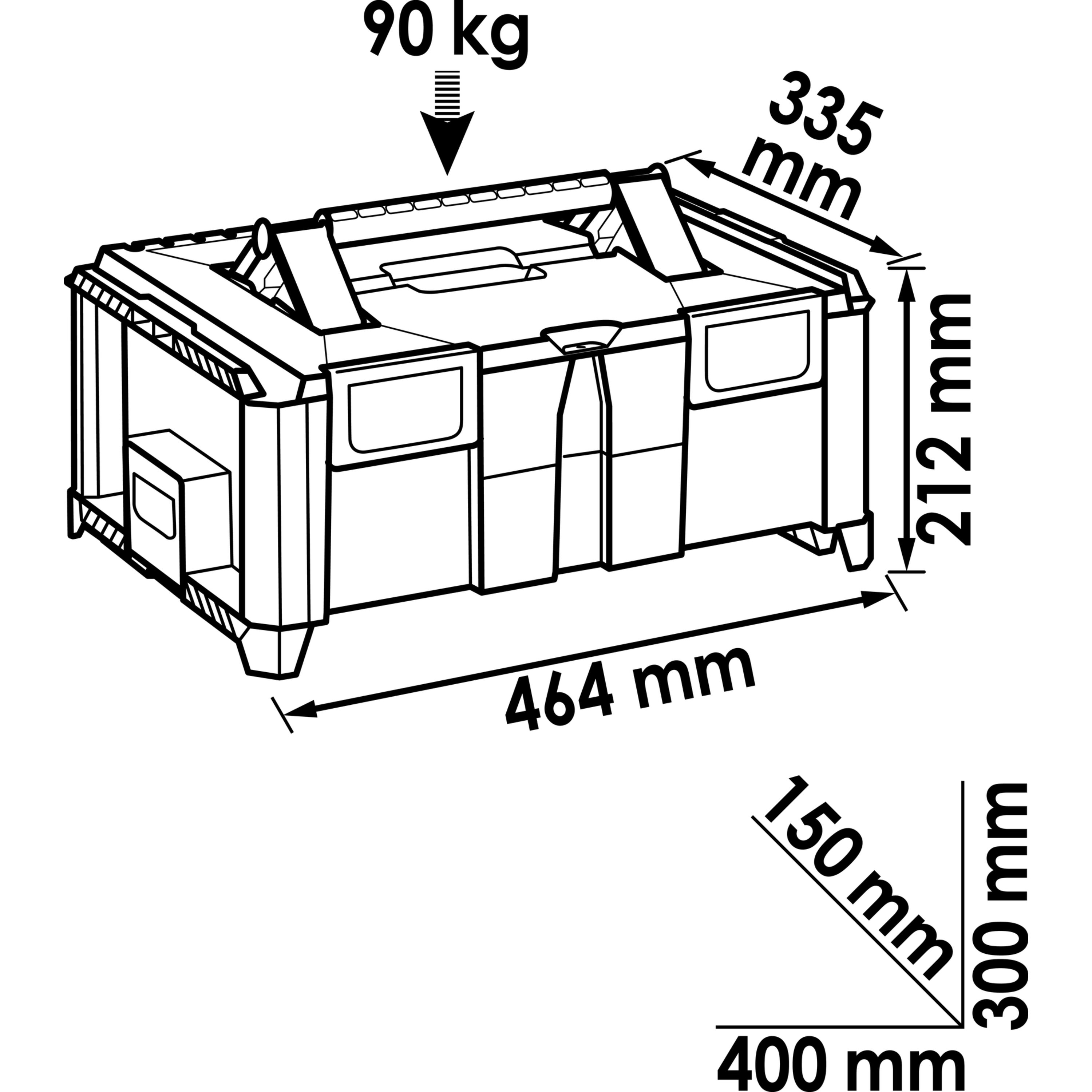

- Lightweight plastic box

- Maximum loading capacity: 90 kg

Design of the drive shaft

The drive shaft is used to transport the applied torque of the motor and the gearbox via the wheel bearings to the wheels. This action should be uniform and without speed fluctuations. A drive shaft can be identified by the two bellows at the ends. One leads to the wheel centre, the other to the differential output

Out with it:

causes of damage and reasons for removal

- Age-related wear, which usually manifests as cracking noises when cornering. Defective axle boots cause water and dirt to damage the hinge

- Improper installation

- Associated work, for repairs to clutch or gearbox

- In the case of front-wheel drive vehicles, "quick starts" damage the drive shaft when making a turn

- Quick and easy removal of rusted drive shafts

- Quick and easy removal of stuck drive shafts

- Corrosion caused by salt requires high forces during removal

- Insert measurement / drawer size: M (282 x 393 mm)